The cereal bar production line includes: syrup cooking,storage,continuous mixing,material double rolling,tunnel cooling,longitudinal cutting,bar separator,guillotine cutting,conveyor. The full automatic cereal bar production line can also coordinate with the chocolate enrobing machine, which can produce all kinds of chocolate enrobed bars.

Features:

1.The complete cereal bar line is a fully automatic line with the PLC control system.

2.The line adopts German technology with the highest performance.

3.The line is multifunctional,it can make cereal bar,nuts bar,seeds bar,energy bar,protein bar,etc.

4.The line can be perfectly connected with the chocolate enrobing line for making chocolate bars.

Cereal bar machine

Cereal bar making machine

Cereal bar production line

Electromagetic syrup boiler

Temperature control mixer

Material lifting conveyor

Complete cereal bar production line for Greece Customer!

Electromagetic syrup boiler + material mixer + material conveyor video:

Cereal bar making machine running video:

Protein energy bar separating + cutting + flow packaging line video:

Recommended by sellers

Energy ball and date ball machine

Small Chocolate Coating Enrobing Machine Without cooling tunnel

Fully automatic kibbeh encrusting making machine

Cereal bar

Chocolate covered cereal bar

Chocolate covered granola bar

Nut bar

Granola bar

Rice bar

We have a standard P401 model granola bar press machine for the customer to choose from for making normal snack bars with the capacity of 100-250KG/H, P402 model granola bar cutting machine for the customer to choose for making snack bars with capacity 250-350KG/H, P403 model full automatic granola bar manufacturing machine for the customer to choose with capacity max. 800KG/H. In addition, the P403 model granola bar production line is the only model to do chocolate bar and candy bar automatically by adding the chocolate coating enrobing machine which can produce all kinds of chocolate enrobed bars.Cereal bar machine display:What kinds of products can our automatic cereal bar production line make?

|

What kind of snack bars are suitable for the automatic cereal bar production line machine?

The automatic cereal bar production line is suitable for the nut or seed mixed snack bars, such as cereal bars, granola bars, oatmeal bars, nut bars, seed bars, etc. The relatively soft material can only be made by our small protein bar machine.What if my products are in abnormal shape?If the shape of the customer's product is abnormal, such as round, spherical, cylindrical, round, etc, then our continuous rice cracker machine will be the suitable machine for the customer. The ice cracker is also the cereal bar forming machine, and the shape and size of the product can be customized through the mold. Please check the details of the cereal bar forming machine.Will it be cheaper if we only need the cereal bar forming machine section or the cereal bar cutting machine section?It won't be cheaper or even more expensive if customers only take the cereal bar forming machine section or the cereal bar cutting machine section. As each separate section need custom-made with a separate control system, and we may custom the belt width, machine height, machine structure, machine materials, etc. Besides, there will be a risk that a separate cereal bar forming machine or cereal bar cutting machine can't match your current machine well. In a word, we strongly suggest customers take our standard cereal bar making machine, it is the most cost-effective choice in a long time consideration.What is the delivery time of the automatic cereal bar production line?The delivery time of our cereal bar machinery is 2-3 weeks. The cereal bar production line will last for 4-5 weeks. We have a small stock of cereal bar machines, welcome to contact us for inventory information.What does the cereal bar machine cost? How do I order the cereal bar machine?

The cost of the automatic cereal bar production line depends on the model selected by the customer. The price of the P401 cereal bar machine is the most competitive, and we have a promotion every season, please contact us as soon as possible to get our latest cereal bar machine prices. To order our automatic cereal bar production line, please send us your detailed company information to make you a formal proforma invoice. The proforma invoice will include the specifications and price of the cereal bar machine, our trade terms, and our bank information. Thank you for choosing our PAPA cereal bar machine!Our company

Shanghai PAPA Industrial Co.Ltd, established in 2014, is located near Shanghai Hongqiao and Pudong airport. Short distance, convenient for customers to visit the workshop. After more than 10 years of experience and technology accumulation, our company has a first-class production base and R&D building, as well as a full set of processing equipment. In addition, we also have a group of senior engineers and technicians who design and improve the best machines according to the different requirements of customers and provide customers with test bases.

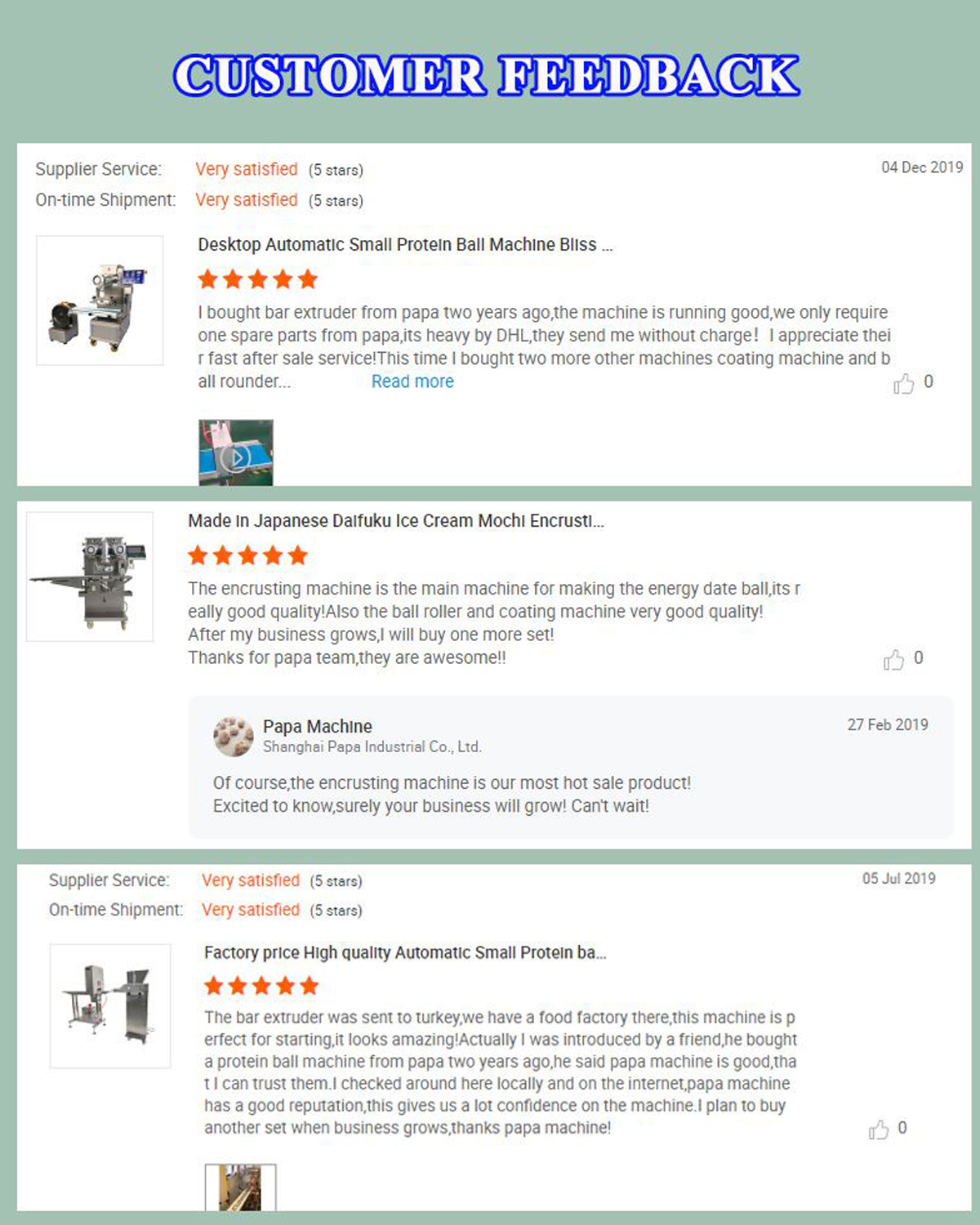

Shanghai PAPA Industrial Co.Ltd, established in 2014, is located near Shanghai Hongqiao and Pudong airport. Short distance, convenient for customers to visit the workshop. After more than 10 years of experience and technology accumulation, our company has a first-class production base and R&D building, as well as a full set of processing equipment. In addition, we also have a group of senior engineers and technicians who design and improve the best machines according to the different requirements of customers and provide customers with test bases.Our customer

PAPA industrial provides complete pre-sales and after-sales services for our encrusting machines, including customer inspection, customer learning, customer training, and guidance on installing and debugging the encrusting machine.